What Are Some Common Applications For A Two Part Epoxy Adhesive Glue?

Two-part epoxy adhesive is a potent bonding agent with superior strength and resilience. Created by mixing two components - resin and hardener - it's designed to securely join all sorts of materials, making it a valuable tool in countless situations. From sticking your car bumper back on to attaching parts inside an aeroplane engine, you can count on this type of glue for heavy-duty results that hold up against the elements.

All in all, two-part epoxy is a formidable contender for working its magic! This eye-opener shows what two-part epoxy adhesives can do in various industries and fields. In conclusion, you'll eventually observe the utilization of two-part epoxy adhesives in applications. It's worth noting that those fastening agents can be exceptionally powerful, sticking around much longer than one would think!

Construction and Building Industry

The construction and building industry profits greatly from the power of two-part epoxy adhesives. They serve several highly beneficial purposes - take concrete work, for example; their incredible adhesive qualities make them ideal for sealing cracks, bridging gaps, and fastening structural elements together. For sprucing up an indoor or outdoor space, nothing beats them when it comes to attaching tiles and decorative objects to surfaces.

Metalwork is another application where these resilient glues excel - from ancient times to today, they have proven unparalleled in joining steel beams or reinforcing bars with sheer strength and lasting effectiveness. Then there's their imperviousness towards water, chemical exposure and extreme temperatures that make them suitable even for the harshest locales!

Furthermore, two-part epoxies boast a long working time, so repositioning can be done before the bond has been set down correctly. Plus, rapid cure times also reduce labor costs - talk about bang for your buck! Not one trade involved in construction could manage without this awesome adhesive weaponry – versatile enough to never go out of style yet robust enough to withstand any onslaught!

Automotive Industry

The automotive industry loves two-part epoxy adhesives. And who could blame them? These adhesives are the strongest bonders, but they're also temperature resistant and ideal for an array of uses - from piecing together plastic parts and metal components to attaching glass windows tightly in place. No matter how hot or cold the environment is, you can rely on two-part epoxies to confidently secure your ride's structure.

Epoxy adhesives aren't just the go-to choice for assembling cars; they can also be a savior in auto repair! Are they replacing windshield cracks or mending scraped-up plastic parts? No problem. Moreover, these marvelous glues guarantee unparalleled bonds between various automotive components. A true pro's favorite!

Two-part epoxy adhesives have become integral to the automotive industry, from car repair to huge manufacturing assembly. Their ability to form powerful bonds between materials is remarkable - not to mention their resistance against heat shifts and harsh conditions! All this makes them reliable for keeping cars safe and running on the roads without hiccups.

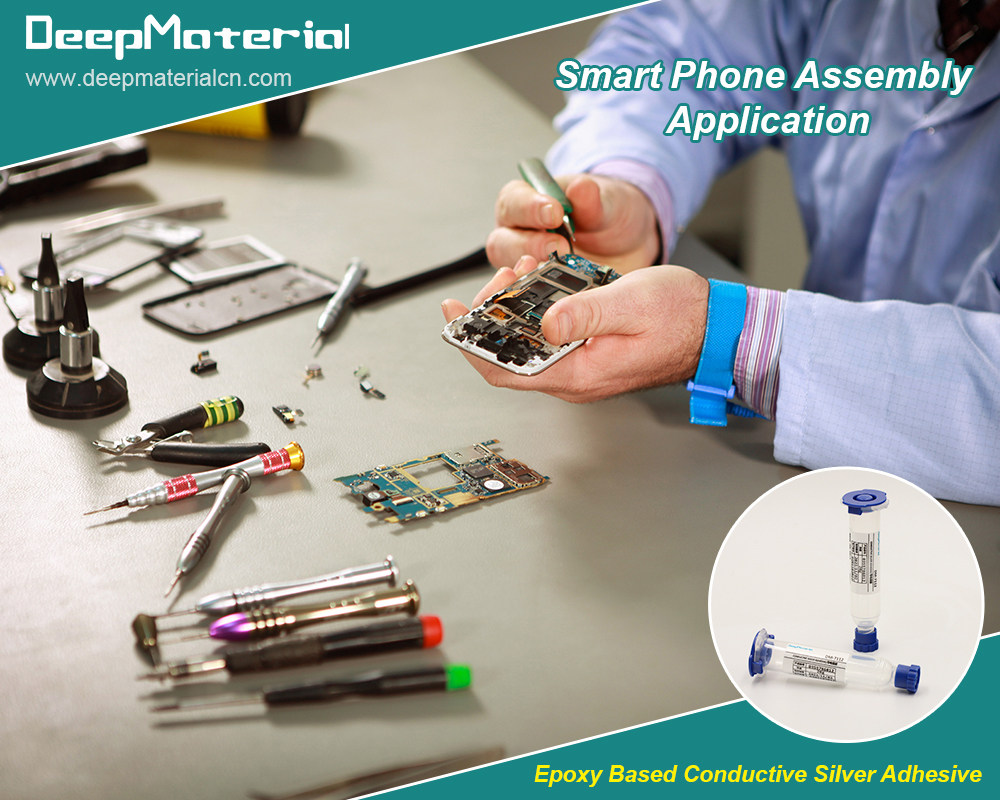

Electronics Industry

The electronics industry, an ever-changing playground of possibilities, relies heavily on the excellent compatibility of two-part epoxy adhesives. Without these adhesives snugly encapsulating electronic parts and affixing them to circuit boards securely, vital components would become vulnerable to hazardous environmental threats such as moisture, dust or any other destabilizing factors - a fate no Bo & Circuits enthusiast should have to behold! These epoxy solutions shield more sensitive elements by providing a robust defence barrier.

Moreover, epoxy adhesives are widely used to bind wires, connectors and other small parts within electronic devices, effectively cementing them into place - no small task considering the harsh conditions of demanding electronics. Not only do they sport excellent durability and temperature control, these efficient glues also guarantee electronics with optimum structuring and dependable performance. A powerful bond is guaranteed to keep these intricate pieces firmly together no matter what!

New-age epoxy formulations provide an ever-growing range of possibilities, helping the electronics industry remain on the cutting edge. With every development aiming for higher performance, slimmer designs and optimum efficiency, epoxy adhesives play a pivotal role and have become an integral component in electronic equipment manufacturing.

Aerospace Industry

The aerospace industry calls for an extra layer of finesse and relies on adhesives resilient enough to withstand extreme air conditions. Regarding capable solutions, two-part epoxy adhesives are the cream of the crop – able to withstand scorching heat, turbulence vibes and a range of chemical emissaries accompanying sky travel. Not only crucial when bonding composite materials like carbon fibre-reinforced polymers (CFRP), these powerhouse glues make all aircraft possible.

Nothing less than utter dependability is expected from this formative field, so with two-part epoxy cementing materials together securely, any aerospace creation can remain rock solid during flight - however fierce those gale force winds become! Indeed, its robust nature has made adhesive used in aviation construction irreplaceable, as safety takes precedence when taking off into the high heavens above.

Marine Industry

Boating is no small matter - ask any sailor! That's because you need an adhesive that can take on the challenge and stand its ground when it comes to the marine environment. Cue two-part epoxy adhesives are lauded by builders and repair professionals worldwide for their remarkable water and chemical exposure resistance. Put, these powerful sticklers are invaluable in boat construction and maintenance projects alike; able to bond fibreglass hulls with a steadfast grip whilst providing strong seals against water infiltration into all parts of the vessel - essential for safety and longevity at sea!

Conclusion

Two-part epoxy adhesives are everywhere - used in construction, automobiles, electronics and the aerospace industry. Their unmatched reliability in sticking two materials together like glue makes them ideal for intricate art pieces and vulnerable surfaces prone to cracking from temperature fluctuations or exposure to water and chemicals. Talk about dependability! Why even bother looking further when you need a versatile bonding solution that can be trusted under all kinds of conditions? the best part is that this technology has been predicted to get better and better in few years from now.

For more about common applications for a two part epoxy adhesive glue,you can pay a visit to DeepMaterial at https://www.adhesivesmanufacturer.com/two-part-epoxy-adhesive/ for more info.

English

English