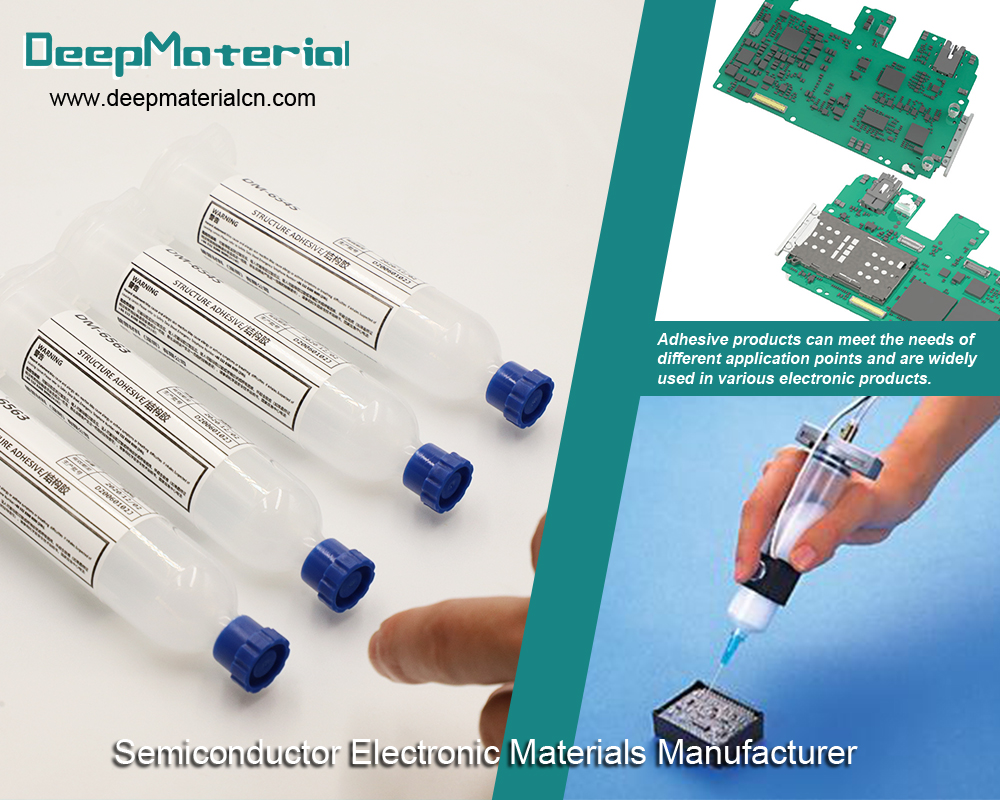

Finding the right industrial electronics adhesive manufacturer with best epoxy adhesive for metal and plastic

It is true that there are numerous industrial electronics adhesive manufacturers around. The advantage of this is that you can get easy access to adhesive and sealant products without hassle. However, there is a drawback. Such is the fact that you could struggle to find a company that will meet your needs. In other words, you will need to take out time to choose from the numerous companies that will come your way. This is not an easy task in any way since you could end up patronizing the wrong company.

What You Need To Know

There is something you should understand about industrial electronics adhesive manufacturers – many of them are not good enough. That is to say, most of these companies are known to manufacture low-quality adhesives. This is why you need to excise patience while finding the best among them.

There is no need being worried though. In case you are looking for the right industrial electronics adhesive manufacturers that are capable of meeting your needs, read the details below. This article will be listing out some tips to help you find these companies. Using these tips will help you get value for money all the time.

Outlining Your Needs

This is probably the first thing you should consider doing. Just as said above, there are numerous industrial electronics adhesive manufacturers around. It is only normal that all of these companies cannot meet your needs. In fact, very few of them will only have products that can address your problems. Therefore, it is crucial that you outline your needs before ever contacting any company in this field. Such decision will help you to know the right manufacturer that is worth your time. The starting point is identifying what such adhesives will be used for.

After that, try to find the right manufacturing company. For instance, adhesives are of different types like epoxy, acrylic, anaerobic acrylic, cyanoacrylate acrylic, Polyurethane and others. To get this stage or step correctly, it is crucial to know the materials that are ideal for these adhesives. For instance:

• Epoxy is compatible with wood, concrete, metal, glass, polycarbonate, porcelain, ceramics, rubber, expanded polyurethane and rigid PVC.

• Acrylic is compatible with plastics, polyester, polyamide, metal and polycarbonate

• Anaerobic acrylic is known to be compatible with metal

• Polyurethane is best for materials like wood, glass and rubber

If you can determine the kind of electronic adhesives that is required for your project, it will be much easier to choose the right manufacturer.

Understanding Adhesives

This is another top tip that can help you spot the best industrial electronics adhesive manufacturers around. Do you plan to patronize any of those companies that are into manufacturing of these products? This is not the problem as there will always be companies you will stumble upon online and offline. Instead, your major focus should be understanding more about adhesives and sealants. For instance, you need to know the various ways that they can be used to improve your electronics project. Lack of adequate knowledge about adhesive products can make you fall into the wrong hands without knowing.

For a start, you need to browse the internet to find out what adhesives are really meant for. This can also help you know the manufacturers that are worthy of being patronized. There is nothing complicated here as you just need to search for their uses online. This takes away guesswork about what they are capable of doing once used in electronic surfaces. Apart from electronics, the roles of adhesives are:

• Window and door assembly

• Assembling of construction materials

• Sealing of leakages on plastic/ceramic surfaces

• Adhering components of agricultural machinery as well as equipment

• HVAC manufacturing

• And many more

Taking Company Reputation Into Consideration

While you might be tempted to find companies that manufacture and sell cheap electronics adhesive products in a bid to save money, it is important to be very careful. This is because something can go wrong and you may end up getting burnt. This has happened to many people in the past who bought low-quality adhesive products from desperate manufacturers. It is crucial to ensure you are dealing with the right companies. Even if you are planning to save some money, it is still possible to patronize reputable companies and achieve such feat. This only requires you to think outside the box.

For instance, you can decide to find out more about an adhesive manufacturer on various websites. This is the internet era when information seems to be everywhere. It will only take you some clicks of the button to know whether a company is truly worth your time or not. Again, you can send them some questions in order to know if truly they are the companies you would like to deal with. If a manufacturer does not answer calls or reply to messages, there is a very high chance that its products are not reliable.

Also, try to find out whether the adhesives are approved and certified by relevant government authorities. Try as much as possible to ensure that your preferred adhesive manufacturer has the backing and approval of government.

Always Consider Your Budget

No matter how reputable or trusted an electronic adhesive manufacturer might be, the truth is that its products will mean nothing to you especially if your budget is limited or low. This is because you will struggle to afford their adhesives. It is the reason why you need to search for industrial electronics adhesive manufacturers that offer such products.

One thing you can do is search online for numerous manufacturers and compare their prices. Also, you can do the following:

• Communicate with manufacturers about possible discounts

• Ask questions about special season offers

• Purchase in bulk from one manufacturer

With these, you will reduce the price that a manufacturer charges for electronic adhesive products.

Conclusion

Having said all of the above, it is very clear that there are many ways to find the right industrial electronics adhesive manufacturers around. Just ensure these tips are applied wherever necessary and you will be fine.

For more about finding the right industrial electronics adhesive manufacturer with best epoxy adhesive for metal and plastic,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/consumer-electronics-assembly/ for more info.

English

English