Can A One Part Epoxy Adhesive Be Used For Both Indoor And Outdoor Applications?

When sticking together two pieces, one-part epoxy adhesives come out above all else. They're renowned for being reliable and robust whilst also having the versatility to bond different materials quickly. But one question we often hear – can a one-part epoxy adhesive be used both inside and outside? In this article, we explain why these glues are hubs of strength- so you can decide whether they suit your application!

What are One Part Epoxy Adhesives?

One-part epoxies are the perfect pick for various uses thanks to their user-friendliness and roof-raising strength. No need to mix, blend and fuss as you do with two-part epoxy adhesives - one-part varieties come loaded and ready to roll straight out of their container! As a team effort between an epoxy resin and a curing agent, they form the strongest bond when exposed to air or warmth.

Unbeatable force is this adhesive's specialty; it excels in applications where intense pressure prevails - giving us ultimate security that things will stay put! It offers a hold failsafe, and its brilliant chemical resistance makes it ideal for placement in chemically volatile environments.

Indoor Applications

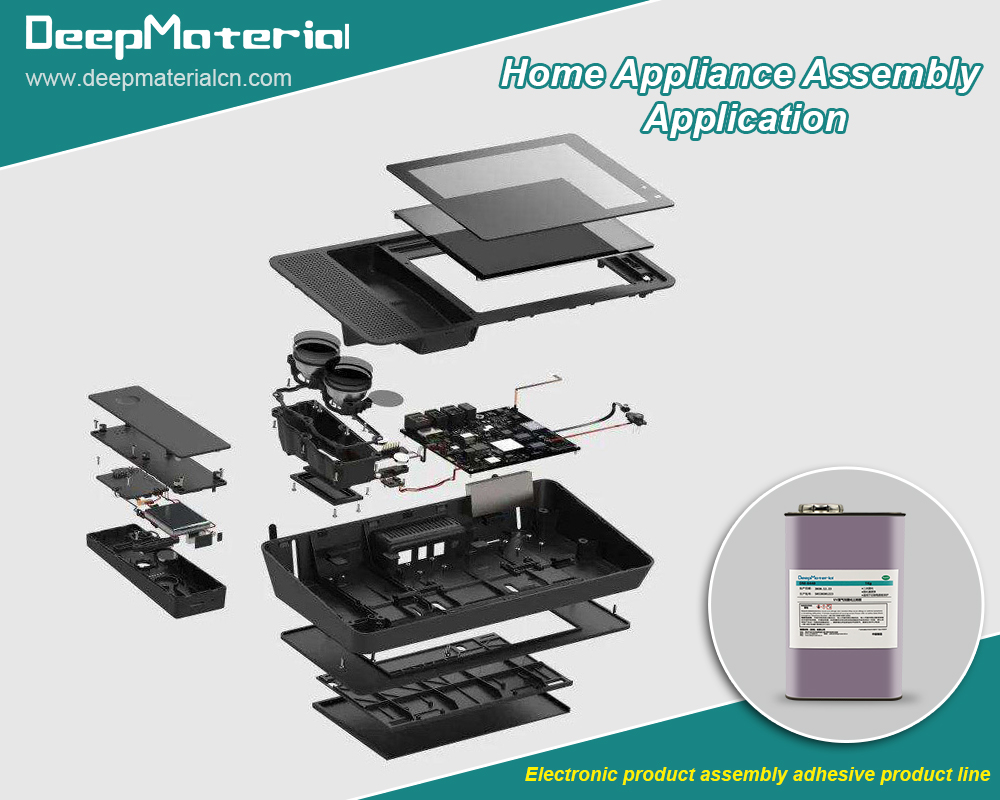

One-part epoxy adhesives are miracle workers for making strong bonds – the kind you need indoors. Not only are they adept at connecting a range of materials like metal, plastic, ceramic and composites – but their solid grip makes them an ideal choice for furniture assembly, electronics manufacture and general repair projects.

What's more? These powerful glues protect against heat and chemicals in harsh indoor environments. Plus, there's no need for extra hassles when applying or waiting around for curing time thanks to their swift application liquid that generally sets fast and cures hard!

Outdoor Applications

Working on outdoor projects can be daunting - it's all about picking the suitable adhesive! It would help to have something strong and durable to endure difficult weather conditions like UV radiation, moisture, wide temperature swings, and chemical exposure. Weaker adhesives just won't cut it; they'll only make a project have a shorter lifespan or, even worse, fail altogether. So, what do you choose instead? One-part epoxy adhesives are famed for their toughness and durability—which is why they're widely used for many applications outside.

But here's the rub: not every part of epoxy holds up that way when exposed to nature's extremes—you must pick one specifically made for the outdoors. Then, and only then, you can guarantee its long-term strength and success.

Weather Resistance

Are you looking for an adhesive that's up to the task of withstanding difficult weather conditions? Then it would help if you considered one-part epoxy adhesives. They work wonders in outdoor applications - no matter what Mother Nature throws at them. Designed and manufactured to survive extreme temperatures, UV radiation, and nasty storms without compromising your bond strength - these specialized adhesives are a real lifesaver in construction, automotive and marine industries where exposure can't be avoided! So, if longevity is important – pick something resistant: a winning choice for projects that need lasting protection from the elements (both good times or bad!)

Moisture Resistance

When it comes to outdoor projects, resisting those pesky wet and wild conditions is a must. You want your hard work to be protected from moisture con artists! Think pesky raindrops, stormy waves—humidity hitting maximum capacity. That's why you need an adhesive with major mojo against water penetration. It's time to choose a one-part epoxy adhesive that stands firmly in humidity levels.

Take marine repairs as the poster child: they can be exposed to nearly any level of H20 onslaught and still, stay put because of this trustable adhesive. As for signage? Don't worry – one part epoxy glues are still here like a champ; raining cats and dogs will not affect your sweet creations! Outdoor construction projects involving roofing materials or siding gain extra points - they thrive in moist climates, where other adhesives sink into submission! These bonds keep strong even when extreme weather dives down barging through … fantastic, right? Don't miss out – grab some high-calibre protection for all your outdoor glue needs before Mother Nature does her thing again!

Chemical Resistance

For many outdoor endeavors, things like caustic chemicals or solvents can cause real damage to the materials that should be firmly glued together. To stand up against these substances, strong epoxy adhesives with particularly impressive chemical resistance have been created. These are helpful in industries such as automotive engineering, aerospace science and even industrial chemistry, wherein they face a harsh environment with many possible contaminants in the air.

A tough adhesive ensures items keep being stuck no matter what kind of setting it's come across - better durability and reliability for the product, plus more money saved on repairs 'n' replacements over time!

Considerations for Outdoor Applications

One-part epoxy adhesives are go-to for outdoor projects because of their hardiness and ability to hold in rough weather. But bear in mind that other factors can affect how well the adhesive works - like the materials bonding together. Surface preparation is critical for a strong bond, too.

Giving your surfaces a good wash or sanding down helps the adhesive grab better - follow those theoretical instructions! Remember to check out the manufacturer's guidebook for application method and curing time since that also plays an important role.

Wrapping It Up

Finally, epoxy adhesives come in different varieties that can work in various indoor and outdoor settings. These glue guns are notorious for their ability to form strong bonds indoors, but hey, don't let that fool you! Some have specialized features like a shield against bad weather, liquid repellence, and chemical-proof effects, making them suitable for outdoor use. When deciding on which one to buy, pick the suitable paste according to the given task and follow instructions closely so your bond is both secure and long-lasting - indoors or outdoors! These are important tips that can help you get optimum results while using such adhesive. You will be ahead of others!

For more about a one part epoxy adhesive be used for both indoor and outdoor applications,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/one-component-epoxy-adhesive/ for more info.

English

English