About DeepMaterial

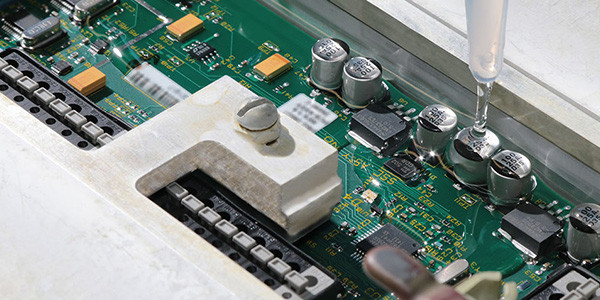

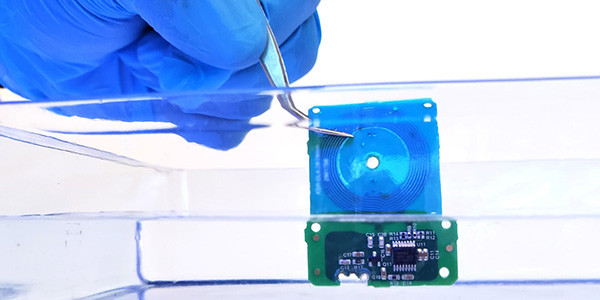

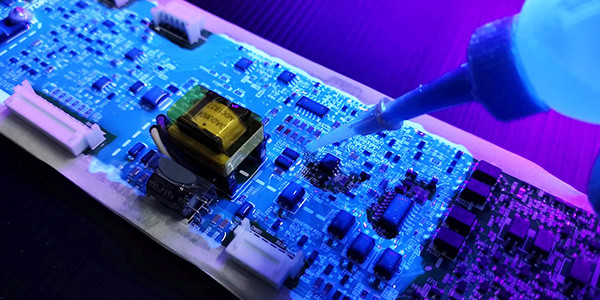

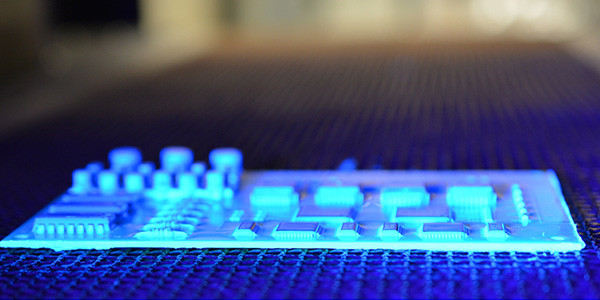

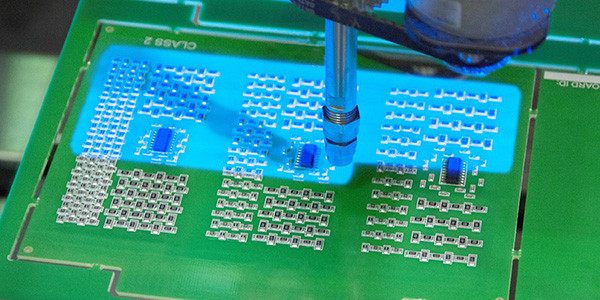

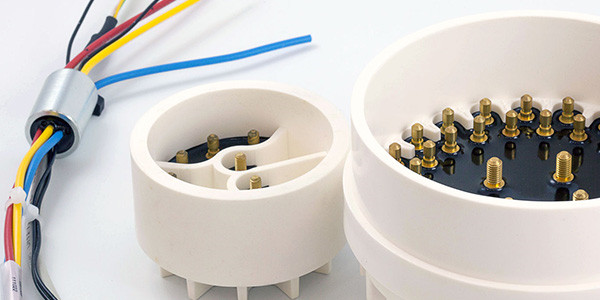

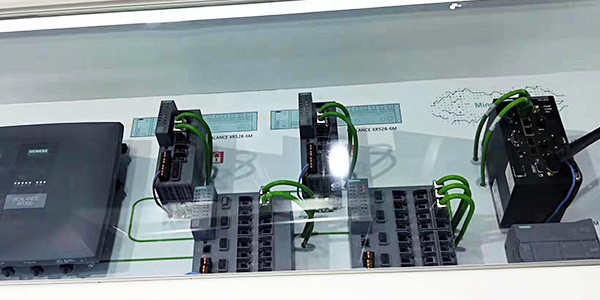

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…

Potting Compound & Adhesive

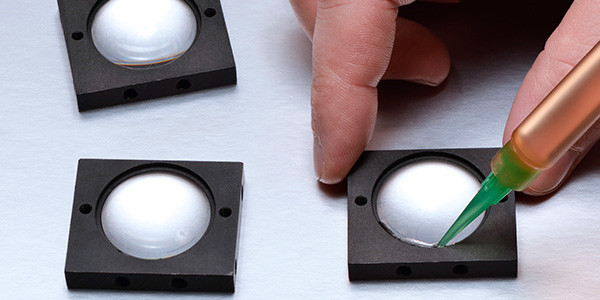

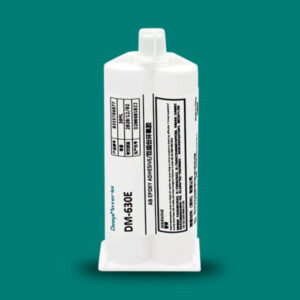

Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Welcome to our comprehensive guide on potting compounds. Whether you’re a seasoned professional or a novice enthusiast, this page aims to answer common questions about potting compounds. Potting compounds are crucial in various industries, offering protection, insulation, and structural support for electronic components. Let’s delve into the world of potting compounds and explore some frequently asked questions. Whether you’re seeking to enhance your understanding of these materials or seeking guidance on selecting the suitable compound for your application, this guide is here to assist you with every step. More…

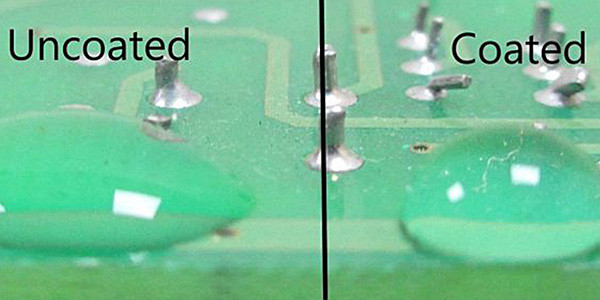

In the world of electronics, where functionality and durability are paramount, one often encounters the term “Conformal Coating.” This seemingly simple solution holds the power to protect delicate electronic components from harsh environments, ensuring their longevity and reliability. However, delving deeper, one realizes there’s much more to this coating than meets the eye. In this comprehensive blog post, we’ll explore the intricacies of conformal coating, its applications, benefits, and everything in between. More…

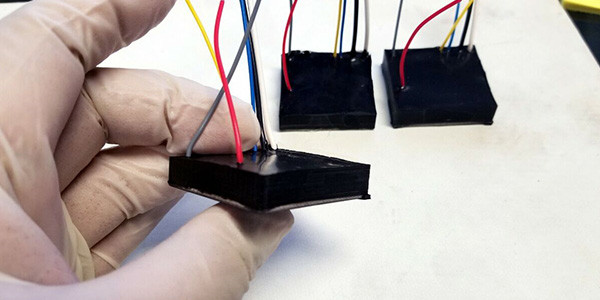

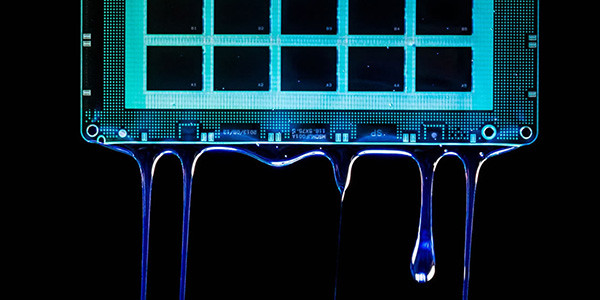

In electronic engineering, component durability and reliability are paramount. Ensuring that delicate electronics remain protected from environmental hazards such as moisture, vibration, and thermal stress is crucial for their longevity and performance. This is where potting compounds come into play, offering a robust solution to encapsulate and safeguard electronic assemblies. DeepMaterial potting compound solutions stand out among the myriad options available for their exceptional performance and versatility. Let’s explore DeepMaterial potting compounds’ countless applications and benefits. More…

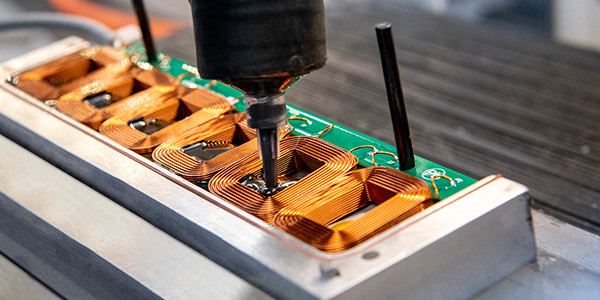

Potting compounds are crucial in various industries, offering electronic components protection, insulation, and stability. Whether you’re an engineer, a hobbyist, or a curious learner, understanding the nuances of potting compounds can enhance your projects and decision-making processes. This comprehensive guide delves into the world of potting compound knowledge, exploring its types, applications, benefits, and considerations. More…

Potting compounds are crucial in various industries, providing protection, insulation, and structural support to electronic components. Among these compounds, the DeepMaterial potting compound stands out for its versatile application and robust performance. This article delves into the diverse uses and benefits of DeepMaterial potting compounds across different industries. More…

More Adhesive Products

DeepMaterial offer different kinds of products about industrial adhesive for electric, UV curing UV adhesive series, reactive type of hot melt adhesive and pressure sensitive hot melt adhesiveseries, epoxy-based chip underfill and COB encapsulation materials series, circuit board protection potting and conformal coating adhesive series, epoxy based conductive silver adhesive series, structural bonding adhesive series, functional protective film series, semiconductor protective film series.

-

Microencapsulated Self-activating Fire Extinguishing Gel From Self Contained Fire Suppression Material Manufacturer

-

Epoxy underfill chip level adhesive

-

Conductive silver glue for chip packaging and bonding

-

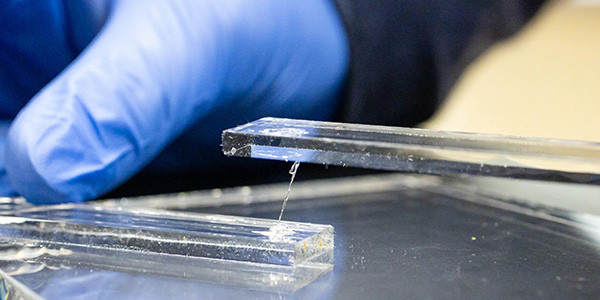

UV Moisture Dual Curing Adhesive

-

Low temperature curing epoxy adhesive for sensitive devices and circuit protection

-

Two-component Epoxy Adhesive

-

PUR structural adhesive

-

Epoxy Encapsulant

-

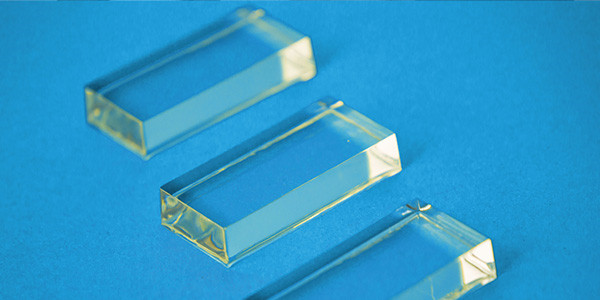

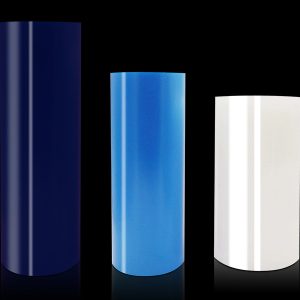

LED Scribing/Turning Crystal/Reprinting Semiconductor PVC Protective Film

-

Semiconductor Packaging & Testing UV Viscosity Reduction Special Film

-

Optical Glass UV Adhesion Reduction Film

-

Anti-static Optical Glass Protection Film

Blogs & News

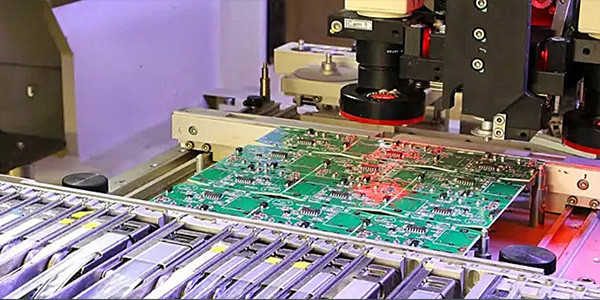

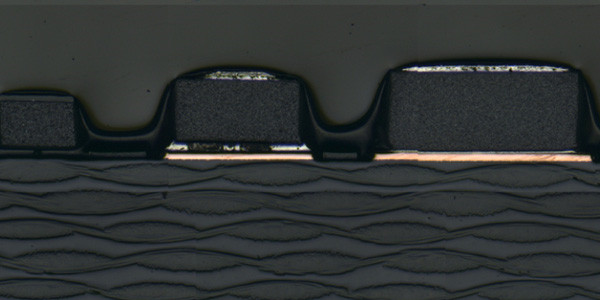

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

How to Select Suitable Potting Materials for PCB According to the Working Environment

How to Select Suitable Potting Materials for PCB According to the Working Environment In electronic devices, the printed circuit board (PCB), serving as the

What is PCB Potting

What is PCB Potting In the realm of electronics manufacturing, ensuring the reliability and longevity of printed circuit boards (PCBs) is of utmost importance. One

The Evolution of Smart Watch Assembly Adhesive: A Key Component in Modern Wearable Technology

The Evolution of Smart Watch Assembly Adhesive: A Key Component in Modern Wearable Technology The wearable technology market has experienced explosive growth recently, with smartwatches

Laptop Tablet Assembly Adhesive: The Key to Durable and Reliable Device Construction

Laptop Tablet Assembly Adhesive: The Key to Durable and Reliable Device Construction In today’s fast-paced world, laptops and tablets are essential tools for personal and

Power Bank Assembly Adhesive: The Essential Component for Building Durable Power Banks

Power Bank Assembly Adhesive: The Essential Component for Building Durable Power Banks Power banks have become an indispensable tool in today’s tech-driven world, ensuring our

Smartphone Assembly Adhesive: Enhancing Durability and Precision in Modern Devices

Smartphone Assembly Adhesive: Enhancing Durability and Precision in Modern Devices The world of smartphones is constantly evolving, with manufacturers striving to create sleeker, more powerful,